Electronics manufacturer: from board design to electronic assembly

Electronics manufacturer for many years, EFS has an experienced team for every stage of your project, from the design of the electronic board to the functional validation of the product before delivery to the customer.

Design of electronic boards

Pre-series and series production

Integration into enclosures or racks

Assembly and final testing for production equipment

FROM PCB TO FINAL PRODUCT

Manufacture from PCB to final product

- Design of electronic boards

- Pre-series and series production

- Integration into enclosures or racks

- Assembly and final testing for production equipment

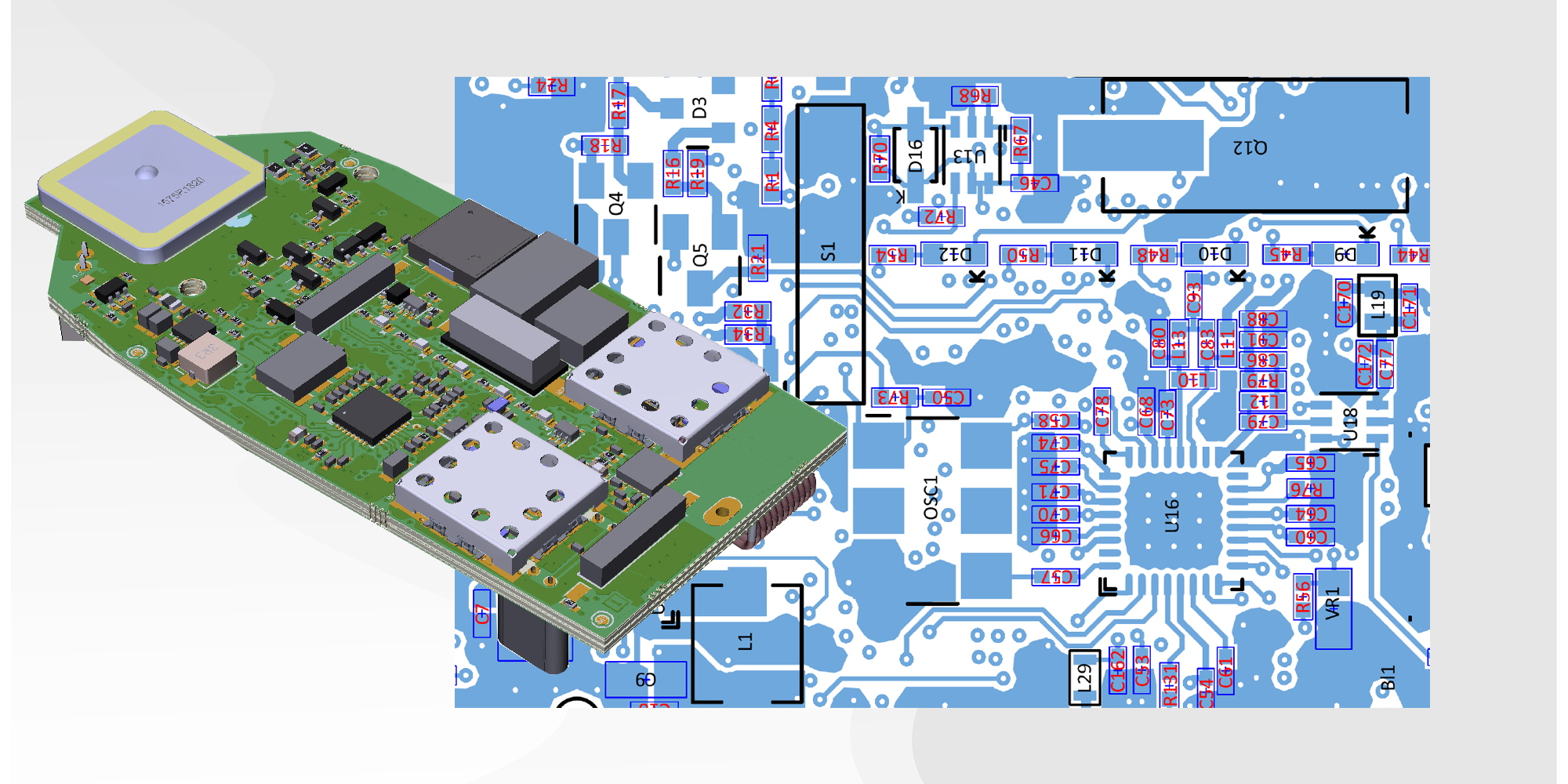

Electronic board design

The prototype is produced by analysing the specifications, creating the mock-up and block diagram, and routing the printed circuit.

The final test validates compliance with your specifications.

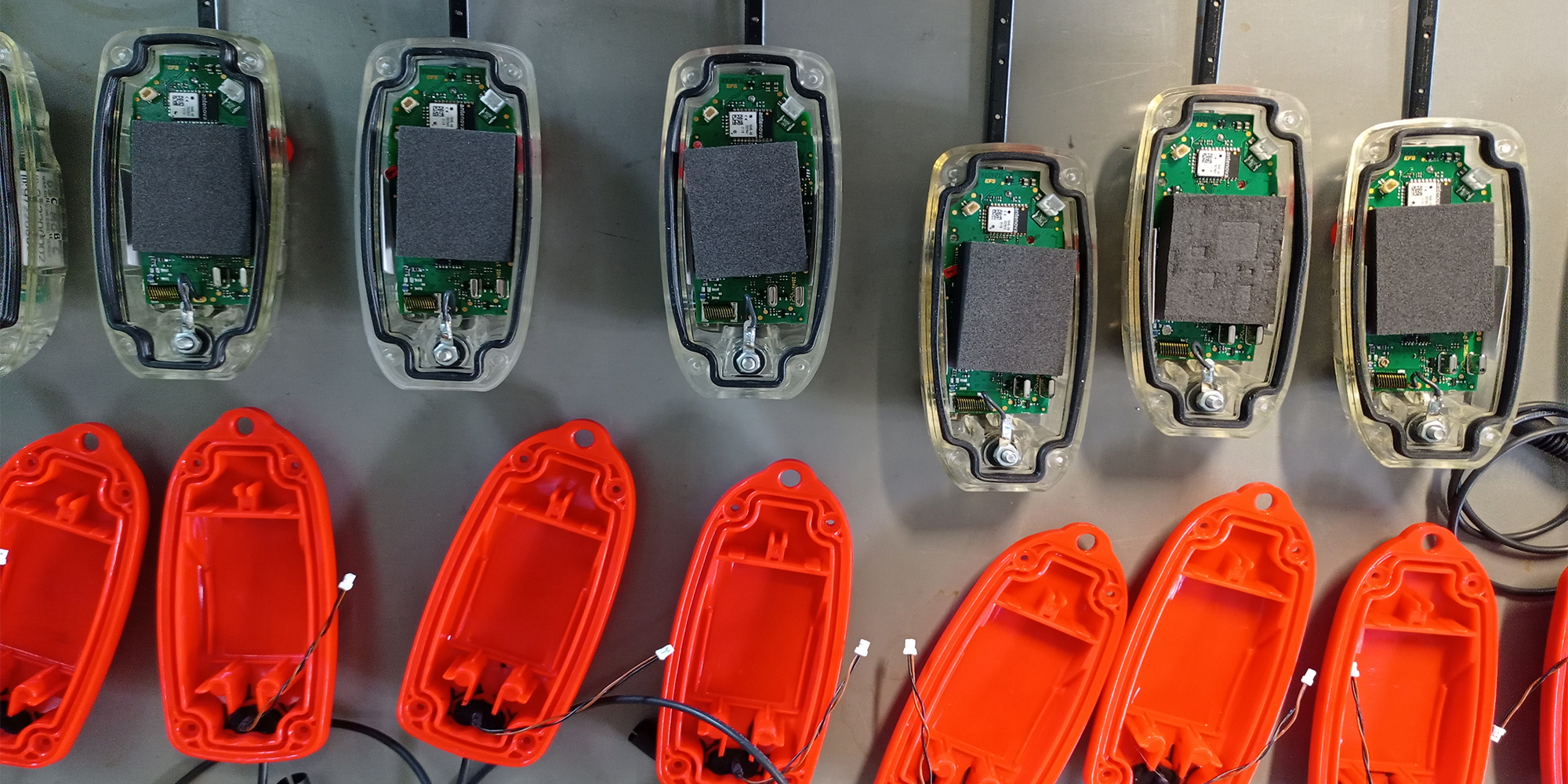

Integration into enclosures or racks

We analyze the environmental, thermal, chemical and vibration integration constraints: dimensions, connectors (choice and location), fixings, internal wiring, etc. to provide you with a product that meets all of your requirements.

he design of the enclosure can be entirely specific depending on the production volume. In this case, we use 3D printing for our prototypes and moulding or overmoulding techniques to make the final product. The design is carried out in-house and production is followed by our qualified subcontractors.

Pre-series and series production

The creation of an industrialization file with specific tooling, the use of an SMD laying machine and a convection oven, wave soldering for traditional products and manual reworking enable us to produce pre-production runs.

Our in-house lines enable us to manufacture small series. What’s more, we have a range of subcontractors sorted by specialty and production capacity according to our customer’s final requirements.

Final assembly and testing for production equipment

We carry out automatic testing and programming of the boards, assembly by clipping, screwing or gluing the casing, leak testing (if required), burn-in testing and dielectric testing.

The finished product is then validated by a functional test, packaged and labelled.

A design office at your service to help you with your project.