Software development and production

EFS has a team of engineers and technicians who design embedded software and human-machine interface software. Our team is involved in both IIOT product applications with software on non-OS microcontrollers and on advanced CPUs running Linux, depending on the complexity of the product and the processing speed required.

This software can be accompanied by FPGAs for real-time processing over periods of a few microseconds. Our team specializes in signal processing for instrumentation management under all conditions.

Embedded and real-time software

Network communication

Human-machine interface (HMI)

Database data management

Web application and OS

SOFTWARE DEVELOPMENT AND PRODUCTION

Our softwares and applications

- Embedded and real-time software

- Network communication

- Human-Machine Interface (HMI)

- Database data management (MES)

- Web and OS applications

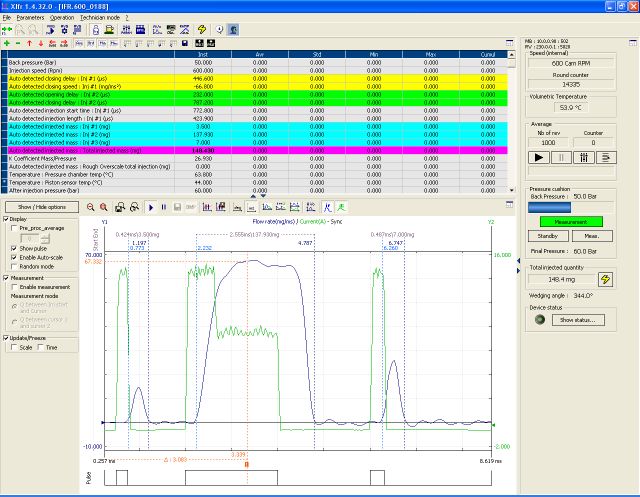

Supervision software

Software for managing a complete test bench, either in the development version for RD or in the production version. This software enables all the sensors supplied on the test bench to be measured, displayed in real time and saved during test cycles.

For production, the software enables fully automated tests with validation or rejection of the part under test. Each sensor and each measurement can have a validation range for a given test step, and each parameter can be adjusted for each test step or fixed for the entire test. All results and parameters are saved during the testing of production parts. Results can be saved to a database and linked to your factory MES.

Equipment monitoring software

This software enables real-time measurements to be taken and updated each time the IFR flowmeter measures an injection, so that changes in all injection parameters can be tracked with extreme accuracy and representative statistical results can be delivered.

The software can be used to display measured values in alphanumeric form or curves acquired over a period of time or as angles over a lap, as required. The software is fully configurable so that you can display only the information that is of interest to you. Only the device control parameters are fixed and always present. This means that the same software can be used for a wide variety of customer applications and user screens, while still using the same software and avoiding the need for multiple maintenance tasks for each application.

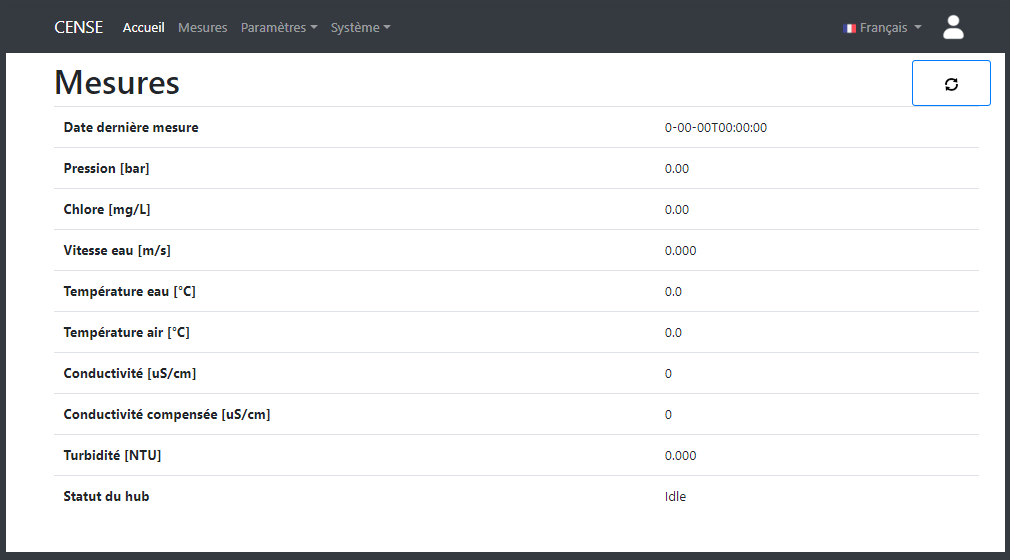

WEB server application

To make the interface more versatile for the customer, we integrate WEB servers on our products that can be connected via WIFI. The advantage of this is that the customer can connect to the equipment using the tool they want and have at hand at the time of the intervention: mobile phone, tablet or PC.

With this interface, they can check all the equipment’s parameters and at the same time retrieve the latest measurements taken. The interface is very easy to use and requires no special training.

This opens up the monitoring and maintenance of our products to as many people as possible.

A design office at your service to help you with your project.