INJECTION SPRAY VISUALISATION: INJETVISION

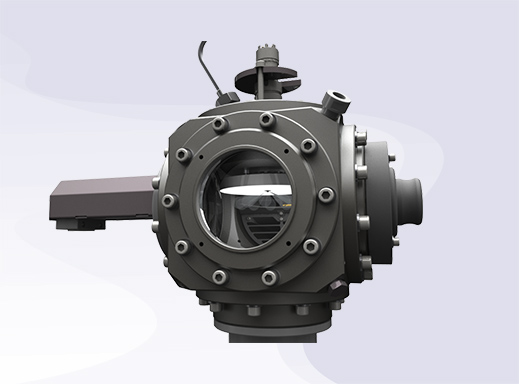

Injection spray visualization system.

INJETVISION is a visualization system for injection sprays that allows real-time observation and analysis of the fuel sprays produced by injectors in gasoline or diesel engines during injection.

The INJETVISION spray visualization system is ideal for automatically studying the evolution of high-pressure gasoline or diesel injector jets, whether single or multi-jet, during the injection process.

The INJETVISION vision system operates under an inert atmosphere (Nitrogen or CO2) up to 50 bar relative pressure (± 0.5 bar).

It is equipped with high-performance software for the complete image processing chain, from image acquisition to image processing.

This system is crucial for improving the understanding and optimization of the fuel injection process in engines

SAFETY

A thermal cut-out, safety valve and rupture disc ensure the safety of the entire system.

SCALABLE

We make the adaptor to fit your injector.

Straight • Motorised rotating • Manual rotating • Offset injector • With nitrogen scavenging

CERTIFICATION

Specific steel cavity to meet all the requirements of pressure equipment certification 97/23/C.

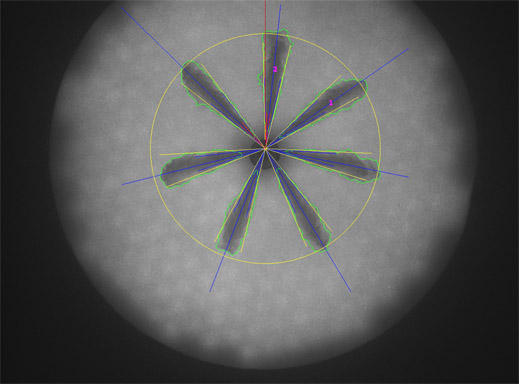

SPRAY ACQ AND SPRAY ANALYZER: THE ENTIRE IMAGE PROCESSING CHAIN UNDER CONTROL

SprayAcq sofware

This software is used to automate a complete sequence of jet image acquisitions. It can acquire Alpha and Lambda images of injection jets. It manages the entire INJETVISION system. It manages the entire INJETVISION system. In summary, it controls

- the injector control pulse,

- the pressure in the vision chamber,

- the pressure in the rail,

- the position of the jet deflector,

- injector rotation,

- the two cameras for bottom and side views of the jets.

SprayAnalyser sofware

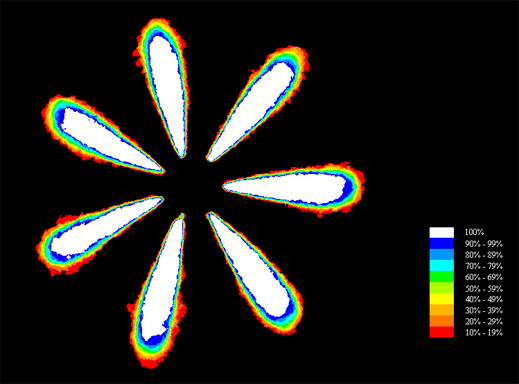

This software enables the morphological parameters of gasoline or diesel injector jets to be studied automatically. It complements the SprayAcq image acquisition software.

- Jet penetration

- Jet penetration percentage

- Jet opening angle

- Surface area and volume of a jet

- Symmetry

- Sheet angle of a jet in Lambda view

- Lambda angle of a jet in Lambda view

- Alpha angle of a jet

- Inter-jet angle

- Circularity

With the INJETVISION injection spray visualisation system, the entire image processing chain is thus mastered from acquisition to image processing and formatting of results.

SEE OUR BROCHURE