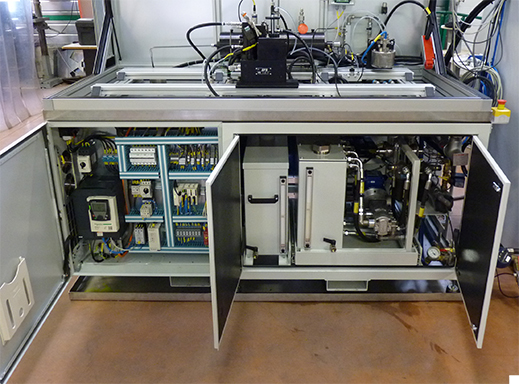

LABORATORY OR PRODUCTION INJECTION BENCH

Secure bench for testing equipment under pressure

EFS has been an expert in engine test benches for many years. This experience enables us to offer compact, complete and scalable test benches for laboratory or production use.

- Cabin door made of safety glass for easy access (butterfly door): protects the user in the event of component breakage under very high pressure (3000 bar).

- Spacious instrumentation table fitted with flowmeters and/or measuring chamber and/or dedicated sensors.

- Oversized EFS 500 cm³ high-pressure rail for greater stability and safety when generating pressure up to 3000 bar.

- Cooling system with heat exchanger (air/water)

- High-pressure management system comprising both a drive motor and a high-pressure pump

COMPACT

Reduced size chassis 2000 mm x 1100 mm

COMPLETE

meets 100% of your testing needs in a minimum space.

SCALABLE

Driven by generic equipment or dedicated ECU, motor power adapted to your needs.

Hydraulic and safety management of laboratory or production test benches

- Sliding hydraulic drawer for easy maintenance and access to all hydraulic parts.

- 40-litre retention tank with level indicator, drain cock and handle for easy removal. Used to collect used fluids.

- 100-litre safety tank fitted with a level sensor on the bench frame for leak recovery and to prevent contamination on the floor.

- Electrical cabinet with various safety and control devices for fully automated bench operation.

- Air extraction vents to ensure good ventilation and avoid any concentration of hazardous gases or fluids in the user area.

- If required, integration of oxygen, hydrocarbon or other detectors to secure the bench for high-risk applications.

EFS has a mechatronics design office staffed by engineers and technicians for mechanical, hydraulic and pneumatic design. Please contact us for further information.

SEE OUR BROCHURE

Envoyer le lien à :